Why Use Diffusion Bonding for Internal Geometries?

In high-precision industries, the demand for clean, compact, and high-performance components continues to grow. Engineers face increasing pressure to integrate more functionality into smaller, more efficient systems—without compromising reliability.

One solution stands out: diffusion bonding, especially when combined with complex internal geometries.

What Is Diffusion Bonding?

Diffusion bonding joins solid materials using heat and pressure—without melting them. Instead, atoms at the interface migrate and bond over time. The result is a seamless, solid-state connection with no filler materials, adhesives, or welds.

This method becomes even more powerful when we machine internal features like channels, holes, or cavities into the materials before bonding. Once joined, the final component contains fully enclosed internal pathways within a monolithic structure.

Why Internal Geometries Matter

Internal geometries open up new design possibilities. Engineers can embed flow paths for gases or liquids, create sealed cavities for thermal control, or integrate vacuum channels—all within a single part.

Unlike traditional joining techniques, diffusion bonding preserves these fine details without introducing deformation or contamination. That’s essential for systems where cleanliness, hermeticity, and dimensional precision are critical.

Where It Makes a Difference

Industries that operate under extreme conditions or demand ultra-clean environments benefit most from this technology.

In semiconductor manufacturing, diffusion-bonded ceramics and metals enable leak-tight, high-purity parts for vacuum chambers and gas delivery.

In aerospace, microchannel components help regulate temperature in weight-sensitive systems.

In energy and power electronics, embedded cooling structures improve heat transfer without increasing part count or volume.

What Top Seiko Offers

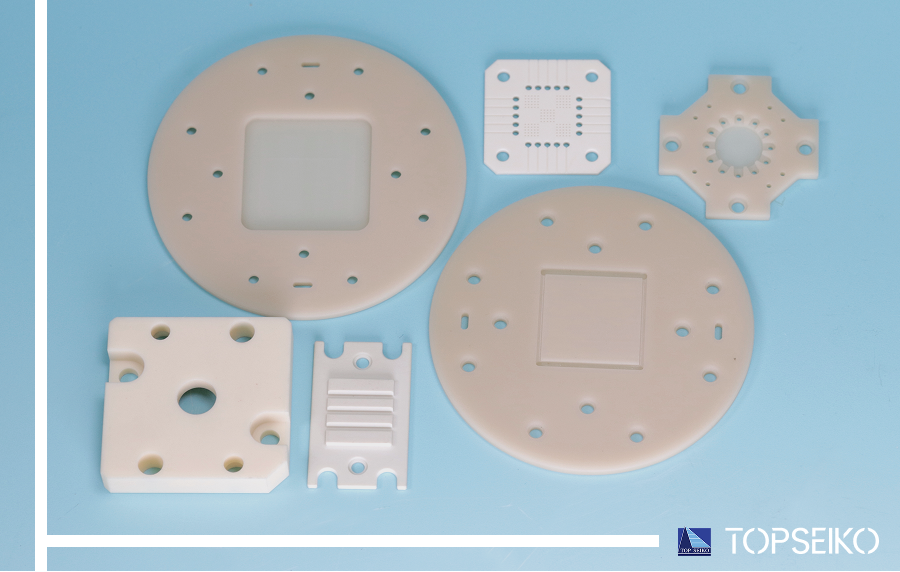

At Top Seiko, we specialize in bonding difficult-to-join materials such as molybdenum, nickel, quartz glass, alumina, SiSiC, and columnar silicon—each bonded to itself.

These materials meet demanding standards for leak tightness, thermal resistance, and chemical stability. We achieve helium leak rates appropriate for vacuum and cleanroom applications, using in-house detectors with high sensitivity.

While current applications focus on bonding two or three layers of the same material, our team continues to explore new combinations and stacking possibilities.

Shaping the Future of High-Precision Systems

Diffusion bonding enables more than strong joints. It allows designers to embed functionality within the material itself—offering unmatched design freedom, performance, and cleanliness.

As industries evolve, we believe this technology will play a growing role in advanced system design, where every cubic millimeter counts.

Looking for a solution that integrates precision and performance?

We’d be happy to talk.