Since our founding, we have accumulated a wealth of experience and technology in complex, high-precision machining of a wide variety of ceramics and high-melting-point metals, aiming to be a niche leader, which is the origin of our company name.

We are continuously researching and investing in new technologies in order to deliver highest quality machining services to our customers. Moreover, by utilizing the technical data and know-how we have accumulated to date, we are able to design and develop machining tools to satisfy customers' needs even for difficult-to-machine products that would normally be very challenge to achieve. In the future, we will continue to respond to our customers' requests and contribute to cutting-edge technological innovations, keeping in mind our motto, "There is nothing that can be processed in steel that cannot be processed in other materials", and striving to be the best technical group in the world through relentless pursuit of excellence.

We are proud of our top-class technical capabilities among manufacturers of ceramics and high-melting-point metals in terms of both dimensional and geometric accuracy. There is no limit to the precision demanded by our customers, which is becoming more and more sophisticated as time and technology change. In order to keep up with such demands, we are constantly pursuing stable high-precision machining and repeatedly conducting test machining to further enhance our technical capabilities.

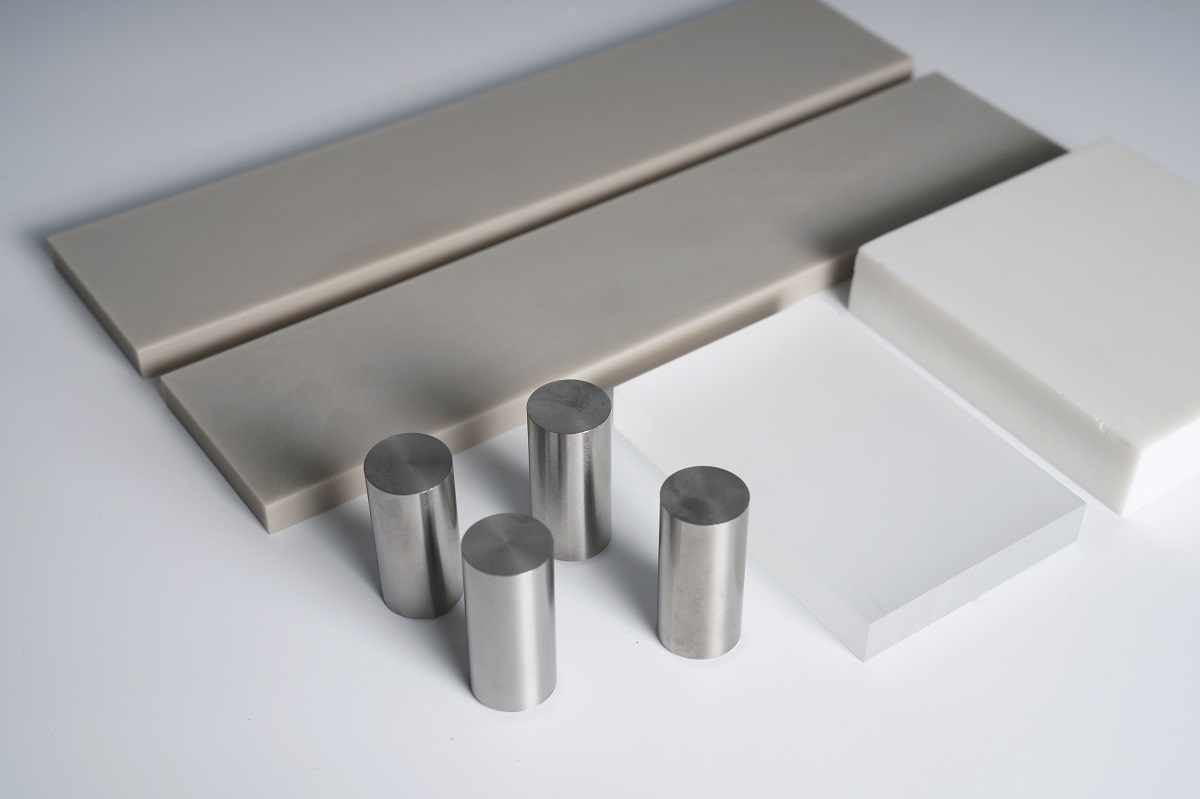

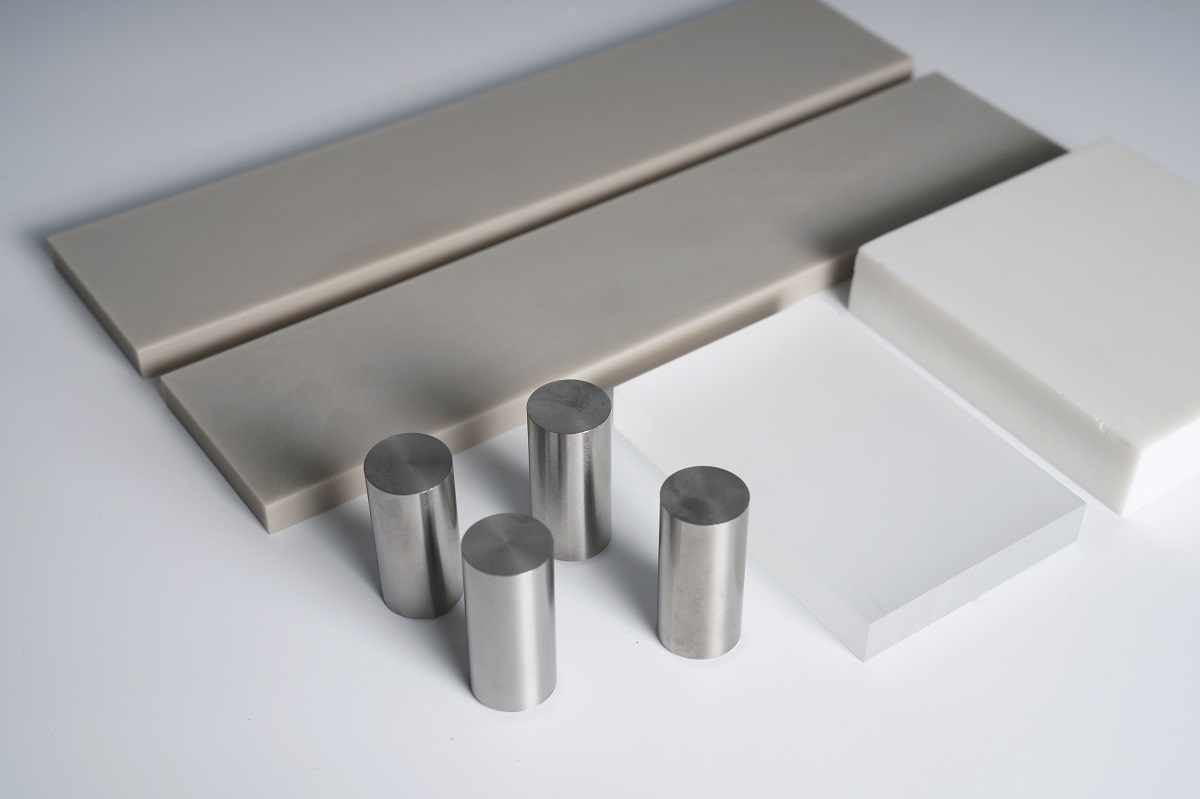

Since we are not a material manufacturer, our customers can take advantage of our unbiased knowledge of exotic hard materials to select the best material for your applications. We have supported our customers with replacing materials for their existing parts. There are many successful cases in which our customers have benefitted through improved functionality of their parts that led to surpass their competitors, or longer service life of the parts which have resulted in lower costs, reduced maintenance and less downtime.

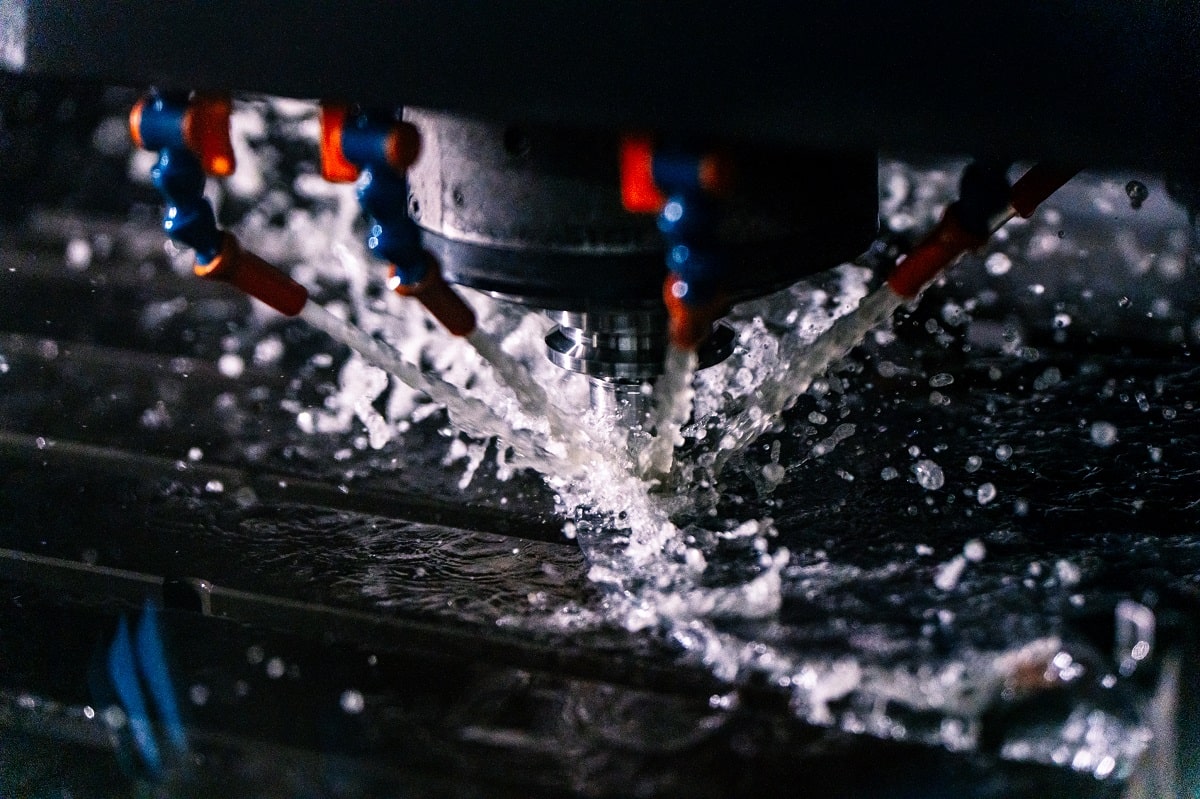

Using machine tools such as 3-axis milling machines and linear specification milling machines, we perform a variety of machining operations such as external shape machining, drilling, unevenness machining, grooving, and screw machining on difficult-to-machine materials. We are also capable of 3D machining of curved surfaces and three-dimensional shapes, as well as drilling holes in such special shapes. In addition, we also specialize in deep hole drilling on the side surface.

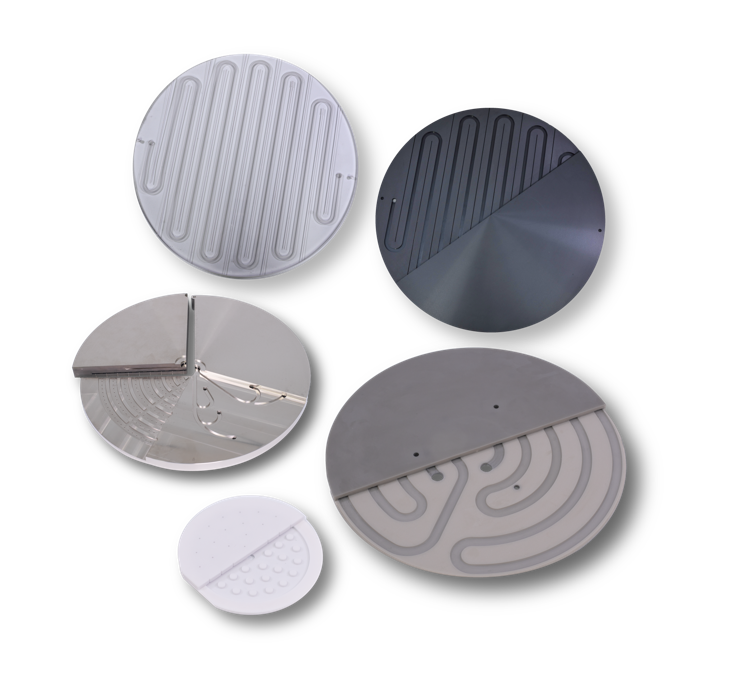

"Diffusion Bonding" is a type of solid-phase bonding technology that joins materials at an atomic level while keeping them in a solid state. It promotes atomic movement at the bonding interface by heating and applying pressure to the materials being joined. This bonding technology enables highly precise and flexible component design, including internal flow channels and deep small-diameter holes with high straightness.

Top Seiko offers material selection assistance service by recommending materials based on material property important for your application. Since we do not produce materials, you can count on our unbiased material knowledge to choose the most suitable material for your application. You can take advantage of our comprehensive precision machining service including material selection assistance & material sourcing for your product development projects! Moreover, there are many successful cases of material replacements which resulted in improving quality, prolonging service life, and increasing productivity / product yield. Let us help you, too!

With our latest machines, various kinds of machining tools in stock, and experienced engineers and machine operators, we help our customers to start their product development projects as quickly as possible. You can count on us for your low-volume prototype machining and high-volume production machining needs. For your challenging machining needs, we carry out test machining. Based on the results of the test, we decide the best machining conditions to meet and exceed your toughest requirements. We even carry out tests until desirable results come out.